Brushless DC Motors: perché sono il futuro della moderna tecnologia di guida?

Poiché i dispositivi intelligenti, i veicoli elettrici, l'automazione industriale e l'elettronica di consumo continuano a migliorare, la domanda di motori efficienti, affidabili e a basso rumore è in crescita. È in questo contesto Motori DC Brushless sono emersi rapidamente come la forza principale per sostituire i tradizionali motori spazzolati. Allora, cos'è un motore BLDC? Perché è così popolare?

Cos'è un motore DC senza spazzole?

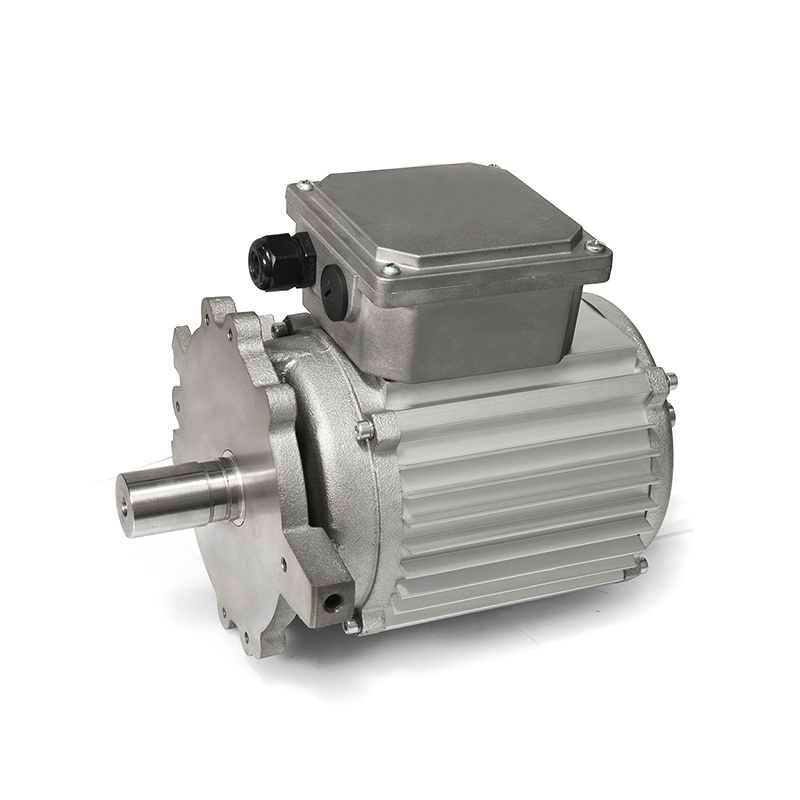

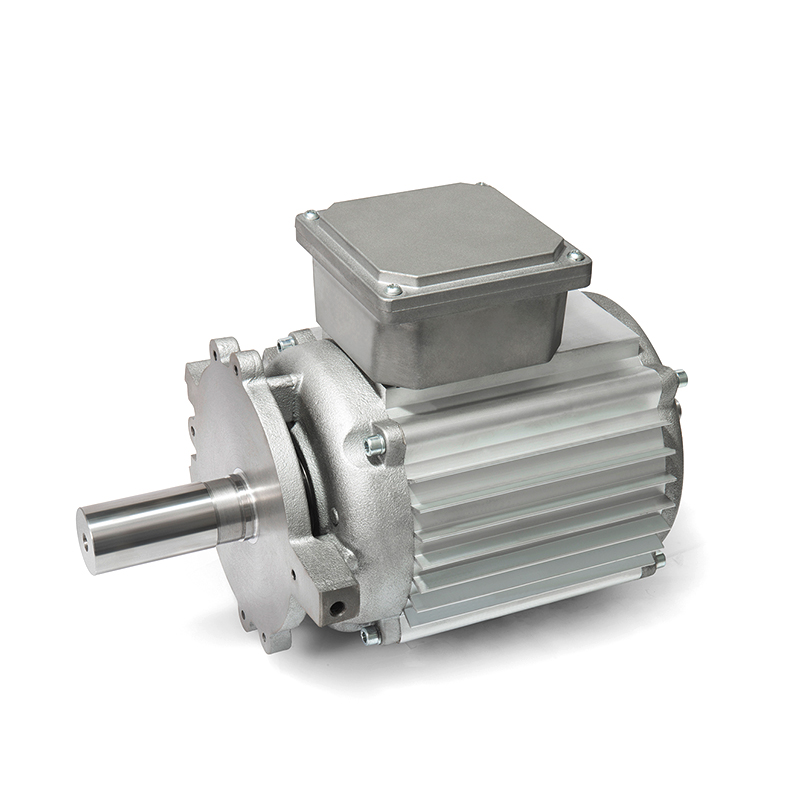

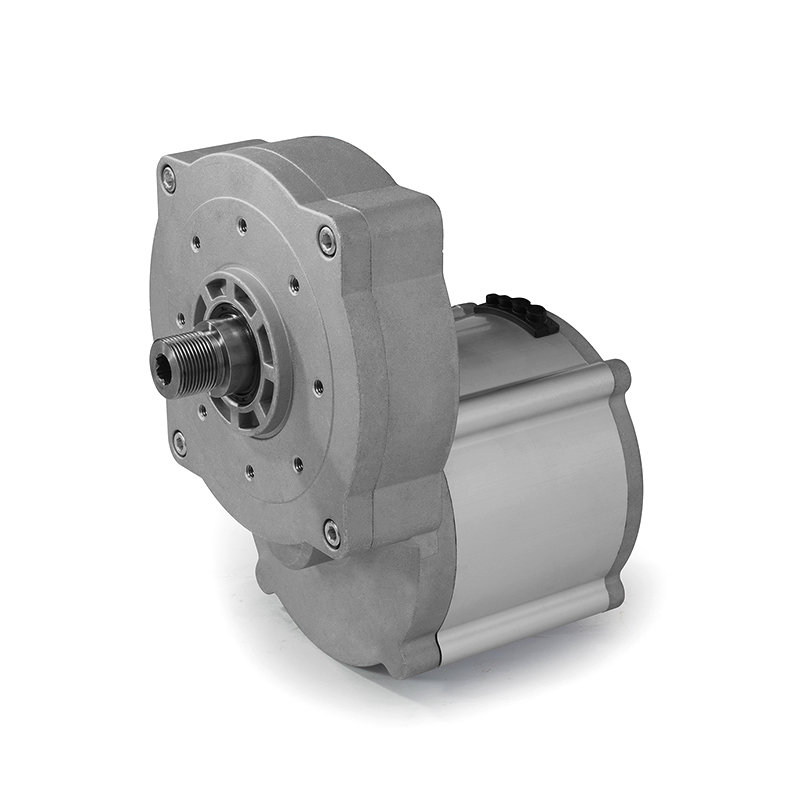

Un motore BLDC è un motore che utilizza commutazione elettronica, nessun commutatore meccanico e spazzole ed è principalmente composto da un avvolgimento dello statore, un rotore a magnete permanente e un'unità elettronica. A differenza dei motori DC tradizionali, BLDC controlla elettronicamente la direzione e la velocità di rotazione del rotore e presenta vantaggi significativi come l'alta efficienza, la bassa manutenzione e la lunga vita.

Quali sono i vantaggi fondamentali dei motori DC Brushless?

1. Struttura senza spazzole, bassa manutenzione

Poiché le spazzole meccaniche vengono eliminate, non è necessario sostituire frequentemente le spazzole di carbonio o pulire il commutatore e il costo di manutenzione è inferiore.

2. Alta efficienza e risparmio energetico

I motori BLDC di solito hanno un'efficienza di oltre l'85%-90%, che è molto più alto dei normali motori spazzolati ed è adatto per scenari che richiedono un funzionamento a lungo termine ed efficiente.

3. Vita di servizio più lunga

Le parti di usura meccanica sono ridotte e la durata media del motore è estesa, il che è particolarmente adatto per attrezzature industriali o incustoditi.

4. Controllo preciso e alta reattività

In combinazione con controller elettronici, può ottenere un controllo preciso di parametri come velocità, coppia e sterzo, che è molto adatto per l'automazione e la robotica.

5. Rumore basso e funzionamento stabile

A causa della mancanza di attrito a pennello, basso rumore e bassa vibrazione durante il funzionamento, è una scelta ideale per occasioni tranquille come elettrodomestici e attrezzature mediche.

In quali scenari sono comunemente usati?

Aree di applicazione

Applicazioni tipiche

Veicoli elettrici

Sistemi di trasmissione elettrica, motori del servosterzo

Elettrodomestici

Condizionatori d'aria, lavatrici, ventilatori elettrici

Automazione industriale

CNC Machine Tools, sistemi di nastro trasportatore

Elettronica di consumo

UAVS, scooter elettrici, robot

Attrezzatura medica

Ventilatori, pompe per infusione, robot chirurgici

Come funziona?

I motori BLDC usano i sensori di posizione (come i sensori di Hall) per percepire la posizione del rotore e il controller controlla e spegne la corrente in base alle informazioni del sensore per guidare il rotore per ruotare.

I moderni controller ad alte prestazioni possono anche essere controllati mediante controllo senza sensori, riducendo la dipendenza dal sensore e migliorando l'affidabilità del sistema.

FAQ

D1: Quali sono gli svantaggi di BLDC rispetto ai motori spazzolati?

Sebbene BLDC abbia evidenti vantaggi, il costo iniziale è più elevato, il sistema di controllo è più complesso e vengono posti requisiti più elevati sul circuito di azionamento.

Q2: come controllare la velocità del motore BLDC?

La tensione di uscita del driver è regolata dal segnale di controllo della velocità PWM e il controllo della velocità ad alta precisione può essere ottenuto in combinazione con un sistema di controllo a circuito chiuso.

Q3: il motore senza spazzole è trifase?

La maggior parte dei motori BLDC sono trifase, ma ci sono anche progetti a due fasi e cinque fasi, a seconda dei requisiti specifici dell'applicazione.

Q4: può essere direttamente collegato alla batteria per l'uso?

No, il motore BLDC deve essere guidato da un controller dedicato e non può essere collegato direttamente all'alimentazione come un motore spazzolato.

Q5: è adatto per condizioni ad alto carico?

Adatto. BLDC ha una buona progettazione di gestione termica e un'elevata capacità di uscita della coppia, che è adatta per applicazioni con carico pesante continuo o inizio e arresto frequenti.

Suggerimenti di acquisto: come scegliere un motore BLDC adatto?

Determinare i requisiti di coppia e di alimentazione: calcolare la coppia e la potenza necessarie dal carico nell'applicazione e selezionare un motore corrispondente.

Specifiche di tensione e corrente: confermare la tensione di alimentazione del sistema e abbinare i parametri del driver e del motore.

Gamma di velocità: alcune applicazioni richiedono un'alta velocità (come ventole), mentre altre richiedono bassa velocità e coppia elevata (come i veicoli elettrici).

Se è richiesta l'accuratezza del posizionamento: per le applicazioni con requisiti di precisione di controllo elevati (come i robot), si consiglia di scegliere un sistema di controllo a circuito chiuso con feedback dell'encoder.

Abbinamento del conducente: dare priorità ai motori che forniscono driver originali o compatibili per migliorare la stabilità e la compatibilità complessive.

Riepilogo: BLDC Motors, la forza trainante del mondo intelligente

Nell'era dell'industria 4.0 e della produzione intelligente, i motori DC senza spazzole stanno diventando i componenti principali dei sistemi di automazione con la loro alta efficienza, intelligenza e affidabilità. Sia in robot ad alte prestazioni, droni, veicoli elettrici o in elettrodomestici e dispositivi medici portatili, BLDC è diventato la soluzione preferita.

Con l'ulteriore ottimizzazione della tecnologia di controllo e dei costi di produzione, la popolarità dei motori BLDC continuerà ad aumentare in futuro, aiutandoci a entrare in una nuova era di unità più efficienti, più intelligenti e più verdi.

-

Feedback

Hotline:0086-15869193920

Time:0:00 - 24:00

English

English Deutsch

Deutsch italiano

italiano 中文简体

中文简体